Display of physical pictures and advantages of explosion-proof vortex air pumps

Release date:2025-06-08Number of views:225

Explosion-proof vortex air pumps are mainly used in factories, underground coal mines, tunnel furnaces, petroleum and natural gas, petrochemical and chemical industries, steel and metallurgical equipment, boiler processing rooms, urban gas, transportation, grain and oil processing, glass industry, textile factories, papermaking machinery, fireworks and firecrackers, special places, pharmaceutical factories and other departments. They are also widely applied.

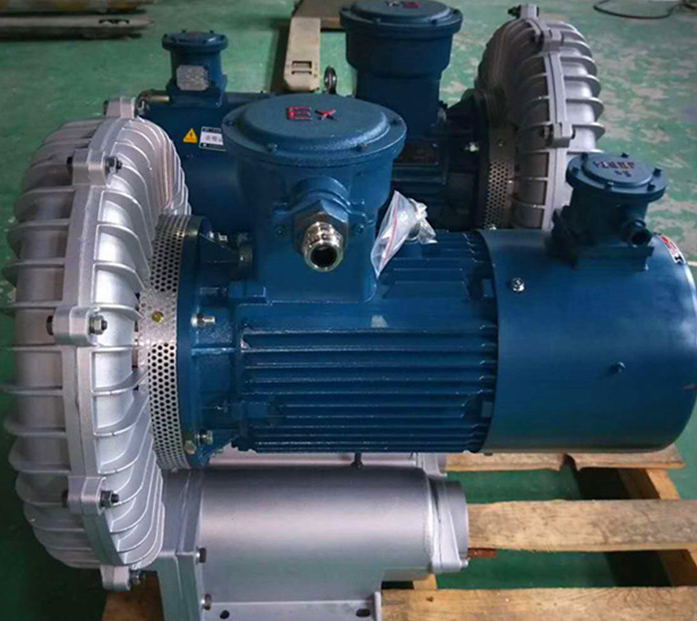

The picture shows a variable-frequency explosion-proof vortex air pump with double impellers

Explosion-proof vortex air pump: It is now widely used in various places such as factories, warehouses, mines, tunnels, vehicles and ships, cooling towers, buildings, etc. In addition, centrifugal fans are also widely used for ventilation and exhaust in boilers, blast furnaces and industrial furnaces. In addition, it is also applied in the cooling and ventilation of air conditioning equipment and household appliances. Ventilation and odor dissipation in the cafeteria; Drying and conveying of grains; And it is often used as the wind source for wind tunnel experiments and for inflating and propelling hovercraft, etc.

It uses an explosion-proof enclosure to separate the electrical parts that may produce sparks, arcs and dangerous temperatures from the surrounding explosive gas mixture. However, this enclosure is not sealed, and the explosive gas mixture in the surrounding area can enter the motor interior through the gaps at the joints of the various parts of the enclosure. When in contact with ignition sources such as sparks, arcs, and dangerous high temperatures inside the enclosure, an explosion may occur. At this time, not only will the flameproof enclosure of the fan not be damaged or deformed, but also when the explosion flame or hot gas passes through the gap at the joint surface and exits, it cannot ignite the surrounding explosive gas mixture.

The picture above shows a single-stage explosion-proof vortex air pump

The main advantages are as follows:

1. The explosion-proof air pump adopts the latest achievements of explosion-proof motors. When the fan is started, if the current is too large, it may cause the fan to overheat and lead to the leakage of flammable and explosive gases, resulting in an explosion. The explosion-proof fan is designed based on the regenerative principle. The single-piece centrifugal fan blade has a small diameter, which increases the air volume and generates high air pressure characteristics. It requires no maintenance! Oil-free! Long service life!! Energy saving! It has features such as environmental protection.

2. The vortex air pump is compatible with the air pressure and air volume characteristics of the Tuo Pu fan and can be applied in any working condition except for the mining environment (the acid and alkali resistance for anti-corrosion can be achieved by spraying anti-corrosion paint both inside and outside).

3. Except for the change in the size of the explosion-proof junction box, the structure of the explosion-proof vortex air pump is consistent with that of the Tuo Pu fan in other parts. Therefore, it can be installed freely and has a small volume.

4. Explosion-proof air pumps and fans, in addition to being equipped with flameproof explosion-proof motors, generally meet the "Exd" requirements, with explosion-proof grades of BT4/CT4.

High-flow explosion-proof large air pump

The picture above shows a standardized large-flow explosion-proof large air pump

Explosion-proof vortex air pumps are suitable for:

Chemical plant, coal mine, tunnel, boiler, canning, glass industry, ventilation and exhaust, automatic cleaning, packaging, fish pond oxygen supply, aeration, garbage decomposition, gas transmission Combustion oxygen reduction machine, forming machine, electroplating tank liquid stirring, atomization drying machine, water treatment aeration, aquaculture, screen printing machine, photoengraving machine, injection molding machine, automatic feeding and drying machine, liquid filling machine, powder filling machine, welding equipment, film machinery, paper transportation, dry cleaning clothes, cleaning purposes, air dust removal, bottle drying, gas transmission, chemical plant, coal mine, glass industry Fireworks and firecrackers, special places, pharmaceutical factories, etc.

The stator and rotor laminations of the explosion-proof motor part are made of high-permeability and low-loss electrical silicon steel sheets, ensuring low motor loss and high efficiency.

The bearings of the electric fan are selected as low-vibration and low-noise bearings of the motor. For frame sizes 160 and below, double-sealed bearings are used, and a wave spring washer is installed at the shaft extension end to apply moderate pressure to the bearing, effectively suppressing the vibration and noise generated during motor operation. For frame sizes 180 and above, an inner and outer cover structure is adopted, and a retaining ring is used to axially fix the bearing position Effectively prevent the axial movement of the motor rotor.

To ensure the safe and reliable operation of the motor, the motor with frame size 180 and above is equipped with an oil injection device in the bearing structure. For motors with frame size 250 and above, the position for the bearing temperature monitoring sensor element is reserved.

Conventional explosion-proof vortex air pump

Motor fans and wind covers: For motors with frame sizes 280 and below, anti-static plastic fans are used, which have a small moment of inertia and low loss. For frame sizes 315 and above, cast aluminum or steel plate welded fans are adopted, which are light in weight and high in strength. The entire series of fans are connected to the shaft with key connections, ensuring reliable operation. The wind hood is made of steel plate structure. Under the premise of preventing the intrusion of foreign objects of a certain size, the ventilation area obtained ensures the smoothness of the air passage.